Industrial Liquid Waste and Wastewater

Currently, most production processes generate different types of waste with different states (gaseous, liquid and solid waste).

Aguasin presents a series of products for the treatment of liquid waste, both industrial and urban. For clarification of water, equipment such as sedimentadotes are used, DAF (dissolved air flotation) or processes of solid-liquid separation such as dehydrators, sludge from treatment plants. To help teams to optimal solids removal efficiency,chemicals that can break down the solids in wastewater flows are applied. The chemicals used are: coagulants and flocculants.

Our methodology is to perform the relevant tests previously, and then choosing the optimal product within the range available. It is convenient to begin by performing the necessary laboratory tests, in order to limit the number of potentially suitable products. The method chosen for testing depends on the manufacturing processes involved. Generally, these processes are:

• Clarification and thickening of effluents or suspensions by flocculation with subsequent sedimentation or filtration, respectively, of solids or particles.

• Mechanical dewatering of sludge or thickened sludge.

It is important to select CLARISOL ® products suitable for each application.

After that, tests are done on the ground whose purpose is to observe and evaluate performance.

|

|

| Bridges Chemicals | Treatability Tests |

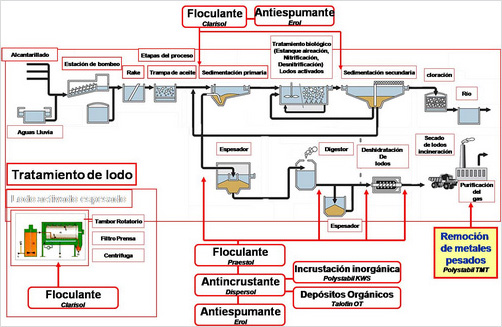

| The overall process of industrial liquid waste treatment. |

|

In Aguasin we count with professionals dedicated to delivering the best solutions. Contact Us and we will answer your request.

Antifoams

Industrial processes in some cases generate foam which must be folded down with the purpose of not to interfere with the process itself, and, in addition, to comply with the current rules of discharge of effluents. Aguasin counts with foaming products to apply in the areas of paper and pulp, sugar and process in biological processes in treatment plants of industrial liquid waste (LIW).

Within the range of products that Aguasin counts with foaming agents can be found in nature and thermal base alcohol.

Aguasin counts with trained personnel to perform laboratory tests in order to define the product that behave optimally with the

feature of the process water or wastewater.

|

|

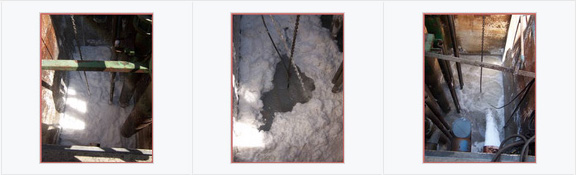

| Clarifiers With Foam | Clarifiers Without Foam |

Antifoaming Siliconised Agents

Siliconised foaming agents are typically used in processes of chemical nature. These processes are oriented to nature biotechnology, such as production processes of enzymes, penicillin, etc.

|

| Sequence of application of an anti-foaming |

Antifoaming agents in Alcohol base

The antifoaming agents based on alcohol are typically used in biological treatment plants.

These products are friendly to the environment and in addition to the biomass present in the biological reactors, without intervening in the

metabolism of the biomass.

|

|

| Laguna With Foam | Laguna Without Foam |

Foaming agents for paper and cellulose

The foaming agents used in the areas of pulp and paper have the feature to be thermal degasifiers and foaming agents. These products are used in the paper machines without interfering negatively in the process. These chemicals can tolerate temperatures above ambient. To evaluate the effectiveness of the antifoam agent in the process of the paper machine, evaluates the dose, injection points and in To do this, you use a computer for measurement of trapped air which indicates, by a protocol to follow, as is the air present in the paper pulp.

|

| Measuring equipment of trapped air addition the trapped air. |

Applications

The flocculating agents have various applications. To clarify industrial liquid waste (LIW) use in equipments of sedimentation or in equipments DAF (dissolved air flotation), whose function is to help separate the solids from the water to obtain an effluent that meets current regulations.

On the other hand, are also used in stages of sludge dewatering where equipment is used such as: filters of dish and framework, centrifuges, etc.

|

|

|

| Settlers | Plate Filters and Framework | Sludge Dewatering |

Coagulants

Chemical in cationic nature that fulfils the function of destabilizing the ionic charge that has the water. These coagulants can be inorganic in nature (salts of aluminum) and organic (polyamides). Will depend on the feature of RIL, the coagulant to use. Aguasin sells the brand CLARISOL®, being the series Clarisol 2000® and Clarisol 5000® suited to this type of products.

Our team of experts evaluates the coagulant that will be used, making the Jar Test trial, where they are experimenting with various products to different doses to deliver an approximation of what it is recommended to apply at the plant.

|

| Jar Test trial |

Flocculants

The flocculants are chemicals - also known as synthetic polyelectrolyte ionic with different loads. The flocculants are used in processes of sedimentation, clarification, dissolved air flotation and in the process of dehydrated sludge from treatment plants. Depending on the nature of the water, will be used flocculants anionic, cationic or non-ionic.

• Anionic Flocculants: Chemicals used for processes of clarification of effluents.

• Cationic Flocculants: Chemicals used for industrial liquid waste (LIW), for example paper and cellulose industry, mainly in stages of dehydrated or tough primary sludge in tables.

• Non-ionic Flocculants: Chemical product used in industrial liquid waste (LIW) of inert nature, for example in industrial liquid waste (LIW) of arenas, where there is no need for a

ionic charge in order to reach the balance load.

With regard to the testing of clarification and sedimentation, the working conditions can be reproduced reliably at laboratory scale. This applies particularly in the determination of the clarification and the speed of sedimentation that can be achieved using CLARISOL® products.

In the case of clarification, using the methodology of Jar Test to determine the product or products that they behave in a manner appropriate to the characteristics of the water to be treated.

This is the standard method for determining the clarification which can be obtained in wastewater, as a general rule, is previously a coagulation by the conditioning with aluminum sulfate,

aluminum polychloride, chloride of iron or other metal salts that form hydroxides. The flocculating agent is used as polymeric flocculating agent or secondary flocculant auxiliary means.

To clarify the water is shaken in the beakers, and added the primary actors to rehearse (metallic salts, possibly correctors of the pH value - as are the lime, the sodium hydroxide or mineral acids).

The flocculation primary is carried out, in most cases, a stirring speed between 100 to 150 rpm, which is maintained for a period of 3 to 10 minutes. Then, the agent is added and the flocculant solution

is shaken rapidly during a period of about 0.5 to 2 minutes. Subsequently, the regime of agitation is reduced to 35 - 60 rpm , in order to obtain a clarification growth or maturation. This last phase can

last between 5 and 10 minutes, after which disconnects the agitator.

|

|

| Jar Test | Water with and without treatment |