Great Projects

Our Projects

The experience, technology, quality and professional capacity and infrastructure that Aguasin counts in, have allowed us develop every kind of project for purification and water treatment to a national and international level.

Our knowledge and experience allows us to design for particular applications in water treatment a unique solution in water treatment.

Aguasin’s installations are present along national and international territory, located in the rainy extreme southern Chile, passing by the driest desert in the world, the tropical weather in Venezuela and even the wild extreme northern Canadian Arctic Pole.

Mining Gaby, II Region, Chile

- Mining Gaby, belonging to Codelco Chile, gave a BOT contract in international bidding to Aguasin for years for designing, construction, assembling and operation of the water treatment plant that supplies 100% of that mine work, located in the II Region of Chile.

- This plant was built in record time. The trial run and tests that were initiated several weeks before the established deadline in the contract and from the beginning operations in March, 2008 this plant has produced the required water by Mining Gaby, fully satisfying clients as much in quality as in quantity.

- The plant was designed for 175m³/h purified water flow through a filtration process, totally automatized double pass reverse osmosis.

Agrosuper, VI Region, Chile

Agroforestal Corneche Ltda. (Holding company of the Agrosuper)

- Clean technologies are chosen in the present, which lead us to take care of the environment for us and the future generations to be able to enjoy a clean environment.

- Industrial activity has given space to development in country economies; however, this has led to produce a greater amount of emissions and waste that must be treated in a way for them not to be toxic for the environment.

- Driven by its spirit of taking care and maintaining a contamination free environment, Aguasin has created projects where, combined with the client intend to provide a nice and healthy environment for the population. One of the great projects in the drinking water line, industrial liquid waste (LIW) and sewage has been the pigs’ faeces treatment.

-

A group of people has been working in this Project to not only sale chemical products but also advise the clients in order to optimize and improve the industrial liquid

waste (LIW) depuration process from breeding and fattened pigs.

Agrosuper counts with activated mud treatment plants, superior technology in comparison to the used in the rest of the industry. The implementation of this technology in volunteer and it’s because of the compromise to the environment as a company. - Aguasin is present in this market, where a 6000 [m3/day] flow is treated, this is divided in four plants that have primary and secondary stages of treatment.

- Aguasin works with the client to find ways to make the process better and be able to drop effluents that are friendly with environment and the population health.

Orafti, VIII Region, Chile

- Orafti S.A., enterprise with Belgian capital is specialized in the production of inuline from endives, decided to install in 2005 an industrial plant near Chillán, VII Region, Chile to have an anti-cyclic production with the north hemisphere.

- To produce inuline it is required high purity water and also a right maintaining and assistance in field base, to do that, Orfti S.A. trusted Aguasin with the design, construction and assembly of the water treatment plant that supplies 100% of the client request.

- The plant was designed and built in Chile and according to the evaluations made by the client, we achieve and go beyond their expectative about design, quality and operation since the start in 2005.

- This plant produces a 120m³/h flow of purified water in 3 trains of 40m³/h each with a totally automatized filtration and treatment by reverse osmosis. The inuline is made with the chicory, an alternative beetroot tuber and from the inulina we obtain aweeteners, fibers and other derived that are used exclusively in the food processing industry.

Diego de Almagro, III Region, Chile

- In an extremely critical situation caused for lack of water to provide to the people of Diego de Almagro, authorities made it urgent to find a solution to make the Codelco Salvador industrial water drinkable.

- Aguasin designed and allowed, in record time, to solve the problem and operate with no setbacks until the day.

- To achieve those requests, Aguasin implemented a reverse osmosis plant in three trains with pre-treatment and telemetric control to condition 33 lps of water with arsenic. This plant has an accumulation and mixing tank system that operate co-ordinately to supply the town with drinking water. The effluents are treated in a reactor to keep in order the environment normative. The plant is locates in Diego de Almagro, III Region, Chile.

Codelco Chile, División El Salvador

- Aguasin has two contracts in its product line for boiler water treatment and cooling with Codelco-Chile.

- The first of them consists in maintaining and the operation of the Caldera Bryan; that belongs to the Planta Concentradora de Molibdeno, running since October 2007; for three years. This is a 1 ton vapour/h.compact boiler. Anticorrosive and antifouling products are applied here, also the operation and the boiler maintaining, and chemical parameter control of the feeding water and system.

- The second one is about chemical product codification and control for the existing cooling systems in Fundición Potrerillos that depends of the Foundry and Refinery Management Operations for 5 years; force since October 2008.

- This considers treatment for open and closed cooling circuits of the oxygen plant, acid plant and Maligas plants and Campanas CPS. Besides, the Termic Central is supplied with products and chemical control.

- Recirculation flow in the cooling towers oscillates between 600 and 3000 m3/h.

- For the control and application of treatment programmes, we have personnel on field responsible for the product preparation, chemical analysis, and dosage system regulations, etc.

Mining Escondida

- Mining Escondida is the mining operation that covers the biggest production in the world. In 2008, with 1.255.019 metric tons of fine copper, represented a 23,5% of the national production, approximately

- Aguasin has a contract with Mining Escondida since July 2007, to run the operation and maintaining of their seven reverse osmosis plants to make drinking water and also for their twelve sewage treatment plants in their several camps.

- Our present contract counts with 22 regular workers and 2 replacements to keep continued shifts during vacations. We have 1 consultant HSEC, 1 planner, 2 shift managers, 2 electric engineers (with SEC certification) and qualified plant operators. Besides we have our own transportation, equipment and implementation to the monitoring and control of the treatment systems, including pit cleaning trucks for mud extraction.

- We deliver a total production of 3.200m3/day of drinking water for the different regular personnel camps and contractors. Also, we have a capacity of sewage treatment of 3.200m3/day, which is recovered for the mining process. This means the water is not infiltrated, protecting the environment and optimizing intern processes.

- Because of our performance and our highest security and environment standards required in mining industry, we have won an award and recognition in Mining Escondida, for accomplish two years with no accidents, period where we can guarantee the complete satisfaction of our client and also the fulfil of every current norm and particular requests.

CMPC Business Group

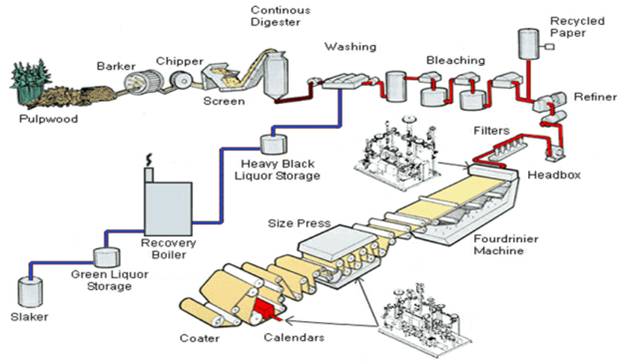

- The enterprises group CMPC has found a strategic partner in Aguasin, capable of answer to the different areas of the company and add value to the final product of the process through the required water treatment in each area of the process:

-

Drinking water

Disinfectants and coagulants approved to use in drinking water. -

Reverse osmosis unit

Antifouling membrane disinfectant cleaners and specially made and approved, by membrane makers, dispersants. -

Steam boiler

Antifouling corrosion blocker, dispersants, alkalinising, packing, resin, ionic exchange and monitoring service and technical support. -

Flue gas scrub water

Antifouling, dispersants, analysis and problem diagnose incrustations and corrosion. -

Process water in paper machine

Antifoam, chemical deaerators, oxidizing and not oxidizing biocides, flocculants and coagulants, application service, monitoring and specialized diagnosed in cellulose and paper processes. -

Liquid Industrial Waste (LIW) Treatment

Flavouring and odors eliminator and flocculants and coagulants for primary and biological processes, antifoam compatible with biological processes..

Aguasin has deployed all its ability to do the tasks in every single given point, combining technology and its implements through our group of engineers and technicians highly qualified and solving clients’ problems orientated inside the CMPC group of enterprises.

Because of the importance we give to people, our Enterprise is capable of receiving associated problems and in that way we can assign the resources and to make flexible the organization to solve the challenges expressed by our clients that use the water inside the CMPC group.