Solutions

The central objective of Aguasin is to deliver solutions to our customers with the latest technology to correct the problems that afflict them. Through engineering, design, production, supervisión of construction and commissioning of these solutions, we ensure that the treatment of water and other fluids is done in the most intelligent way and with the best quality in the market.

Always respecting and caring for the environment, Aguasin ensures superior service delivery through the use of existing quality global standards, as the international certification ISO: 9001-2008.

In Aguasin we count with professionals dedicated to delivering the best solutions. Contact Us and we will answer your request.

Water Process

All industrial activities demands water for the development of their products. According to the stage of the production process, the water must be conditioned,

that is to say, it must meet certain physical and chemical characteristics. As an example we indicate that the water for steam generation, cooling, washing, dilution,

transport and when the final product includes, among others, must meet very different qualities.

One purpose of Aguasin is to condition water to deliver with the precisely characteristic that each of these processes requires. For this, we have the products,

equipment, chemicals and services that allows to reach these requirements succesfully and with quality and efficiency.

Water Waste

Following the development of production processes simultaneously generate waste, wich should be disposed in a safe and sustainable way.

When the liquid waste is considered RIL (liquid industrial waste) and becomes waste water. Therefore, the physicochemical characteristics of the wastewater are very

dependent on the production process in which it was used and its treatment is considered as a solution "case by case", important and necessary to mitigate pollution of rivers, lakes and seas.

Aguasin developing this concept and using technologies, products and services to recover wastewater qualities, so that they can be discharged to natural paths, without

causing impact to the environment, or so they can be reused in the same production processes.

|

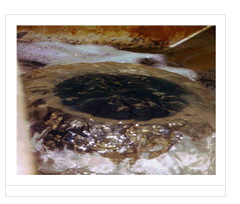

| Avoid this danger to the environment |

Boilers

Used water requires a conditioning that depends on the characteristics of the boiler and makeup wáter; minimizing the possible impact of contaminants in the life of the equipment,

operate efficiently and to avoid unscheduled downtime . For scale control in boilers of low and medium pressure, is sufficient to use softened water in the replacement, however in

high pressure boilers requires a higher purity water, being required total demineralization of replacement water. The residual dissolved solids (hardness and / or others) should be

fitted with chemical dispersants and incrustation inhibitors.

Meanwhile, to control corrosive agents, mainly oxygen and CO2 partial deaeration is performed by feeding water to the boiler using systems operating with vacuum degassing and temperature.

These devices remove much of the gases dissolved in the water, low residual must be removed with the application of chemical oxygen scavengers and corrosion inhibitors.

To achieve adequate control of the chemical treatment program, is needed to maintain levels of products and concentration cycles within an optimal range. Automatic controls bleed,

can keep the concentration cycles established to avoid overconsumption of energy.

Aguasin supplies a range of equipment and services necessary for the proper operation of a steam generator and heating. Among them, we can mention:

• Softeners

• Demineralizers

• Reverse osmosis equipment

• Degassers

• Chemicals Products

• Dosing Systems

• Automatic purge control

• Field Service of monitoring and control

Contracts (EPC, BOT, BOO)

The implementation of the solutions for the treatment of process water, wastewater and water treatment, require high capital investments. In parallel,

these investments are profitable to the extent that they operate efficiently and seek its maintenance over time. To achieve this, Aguasin is involved

in contracts with customers who pursue these purposes. These contracts can range from conceptualization and development of engineering (basic and detail),

the management and construction of the plants, until delivery to the customer or end user (EPC).

Aguasin can also participate in contracts to develop the concept and engineering, and also concurring with capital goods (investment) to complete the final

implementation of the solution. These contracts of supply treatment plants ends with the transfer of the property to the user (BOT) or they operate indefinitely as external service user (BOO).

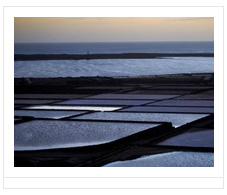

Seawater Desalination

Industrial development and population growth have reached a level where water availability has become increasingly scarce, or water demand (for industrial or human)

in arid areas where it is not readily available. In front of this reality, is that technological development has led to the oceans as a source of process water or

consumption. Since the sea water containing a high salinity, the packaging has an additional complexity to conventional treatments.

Aguasin is the first company in Chile that have used technology of reverse osmosis membranes to remove dissolved salts in water. Today, this technology is used to

desalinate sea water and turn it into water fit for human consumption and production processes.

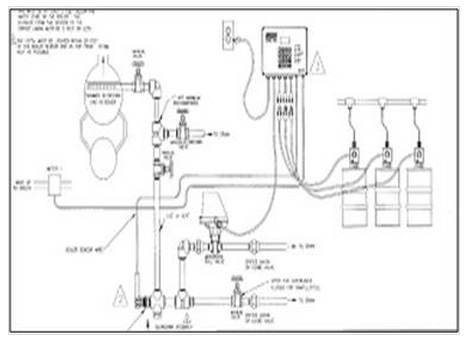

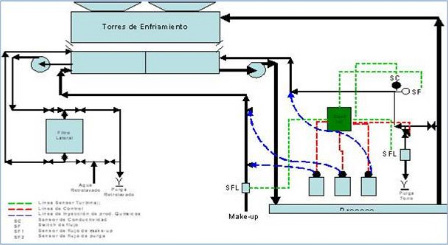

Cooling

The existing cooling circuits in industrial plants can be of various types, the most common are closed loops, cooling towers and evaporative condensers.

Usually, the water used in open circuits corresponding to previously hard water softened, which has strongly fouling potential to mildly corrosive.

Meanwhile, closed circuits uses water characteristics, generally with a tendency to cause rust.

In open systems is necessary to maintain adequate concentration cycles for proper action of the chemical treatment. When the cooling system is exposed to

a high concentration of suspended solids, requires the installation of a side filter system. In general, the filtration rate varies between 5% and 10% of

the recirculation flow.

To monitor the effectiveness of the chemical treathment applied, is performed on-site monitoring by chemical analysis and control of corrosion coupons and embedding.

Aguasin supplies a range of equipment and services necessary for the proper operation of cooling circuits.

|

| Diagram Cooling Tower |

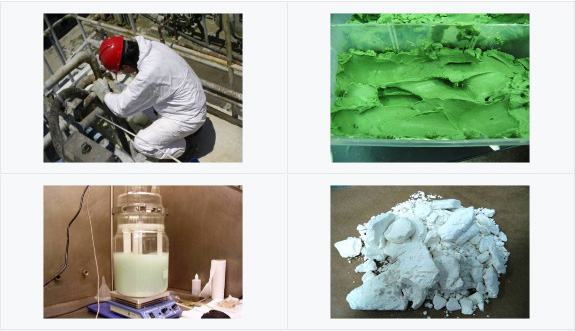

Laboratory

Special projects of monitoring and development

LAB-AGUASIN performs specific developments in the treatment of different phases accuse processes, by precipitation synthesizing, analyzing transport of salts

in mineral products, implementation of specific analytical techniques in effluents, etc.

To design and implement trials LAB-AGUASIN is supported by BAMAG, PUROLITE, BWA and AVISTA, world leaders in water treatment and purification.

|

| Development at laboratory level and pilot project Bamag. Optimization of effluent treatment plants |

Implementation of Laboratories in the Field

Within the scope of the LAB-AGUASIN is the implementation and operation of field laboratories. Design is performed with instrumentation and specific equipment to meet

customer requirements.

The operation of field laboratories reach the requirements of analytical quality control, verification of testing methods and interpretation of results.

|

| Laboratory field. Plant Antihue, Colbún. |

Plant Operation

Aguasin offers a full service operation, supervision and monitoring of plants. This service usually is physical-chemical, biological, and reverse osmosis in water process. This is supported by precise control and recording parameters and inputs. We also have instances that allow a complete training of supervisors and operators, plant optimization and continuous operational improvement.

Pools

Your water shouldn´t only look clean, must be clean!

In Aguasin we have developed this section in particular, which we give very simple guidelines to maintain and care for your pool. For this, it is important to know the concepts

of water chemistry and in better shape comprising different phenomena that occur when adding chemicals, which are necessary to condition it.

Just doing a chemical analysis of water, making maintenance and adding chemicals, you can keep the wáter of the pool sanitized, clean and suitable for a family to enjoy it.

Always keep in mind the three concepts that ensure proper operation and maintenance of the pool:

1. Physics - filtration and recirculation water efficiently.

If there is no effective circulation and filtration (for example, if the filter pump is too small) or if the pump is operating a few hours a day, the chemicals may not work properly and the pool will get dirty.2. Chemistry - proper chemistry balance of the water.

The pool must have is water balanced, with the pH and alkalinity within established ranges. This is very important for the chemicals to work properly and thus allows that water is always kept clear.3. Biological - adequate disinfection, sanitization and oxidation.

The pool water is an "stuck" water because they do not have a permanent renewal. Therefore, we must treat it with proper disinfection for water to remain without any microorganism and is a healthy place for family health.Our Solutions for Swimming Pools

Secure Your Pool

Safety first!

Fun and safety in your pool must go hand in hand. So, whether you're manipulating chemicals or watching their children how to play in the water, always keep in mind the following safety tips to keep your family and pool with the best conditions of safety and cleanliness.Handle with care

One of the most important aspects of security in your pool, but often forgotten or neglected, is the manner in handling the chemicals. Here are some tips to keep your pool pure and safe:1. Apply products using rubber gloves and safety glasses. Protect your health.

2. Always add chemicals to your pool separately, directly to the water. The mixture of chemicals can cause dangerous chemical reactions.

3. Keep chemicals out of reach of children.

4. Don´t overdose products to your pool. The theory that a little more is better is not valid in the case of your pool.

5. When measuring the amount of chemical to occupy, use a container or plastic measuring cup dry clean. The use of contaminated or wet items can be dangerous.

6. Avoid breathing fumes and / or rub your eyes, nose or mouth when handling chemicals. When opened, put away your face from the container.

7. If you spill a chemical, clean it immediately and dispose of it carefully. Most small spills can be diluted with water. Never use a vacuum cleaner to clean the spill.

8. Do not smoke around chemicals. Some chemical vapors are highly flammable.

9. Store chemicals properly. Close them tightly when not in use and store in a cool dry place. Some products are corrosive, so it should not be stored near metal objects such as bicycles, garden tools, vehicles, etc.

10. Have the pone number toxicological emergencies CITUC always in hand: 635 3800.

Make safety a family affair!

The most important of safety around your pool is to use your common sense. Note the following:1. Be sure to follow the companion method. Always swim accompanied by someone.

2. Always supervise children around water. No matter what age, adult supervision can prevent injuries due to violent games, or when the kids get tired.

3. Do not allow the use of any items of glass around your pool.

4. Keep a rescue pole (as used by lifeguards) and a rigid foam lifesaving emergency near.

5. Use floating markers to indicate where deep water starts.

6. Use depth markings indicating the depth of water.

7. Ensure that at least one member of the family knows first aid.

8. Separate pool area with grills, and keep locked accesses.

9. Keep pool chemicals in a locked space away from water.

10. Keep a phone close at all times.

11. We recommend using pool alarms, doors and / or access to alert any improper entry to the pool, especially if there are children in the house.

A little planning, prevention and a lot of monitoring will keep this recreational space as a safe place for your family and friends.

Maintaining Your Pool

Maintaining balanced pool water is essential for the product to function properly. Maintaining the correct levels of pH and alkalinity can prevent surface

deterioration, corrosion, staining, irritation of eyes, skin and water turbidity.

PH is a value indicating the level of acidity or basicity of the pool water. Alkalinity is a measure of alkaline material dissolved in water, carbonates, bicarbonates and hydroxides.

Frequently measuring some parameters of your water is the key to maintain your pool. It is necessary to measure and adjust according to the following table:

| Test | Frecuency | Pool Type | Range |

|---|---|---|---|

| pH | 2 times per month | All | 7.2 – 7.6 |

| Alkalinity | 1 time per month | Plastic | 80 – 120 ppm |

| 1 time per month | Cement / Vinyl | 100 – 140 ppm | |

| Free Chlorine | 2 times per week | All | 1 – 3 ppm |

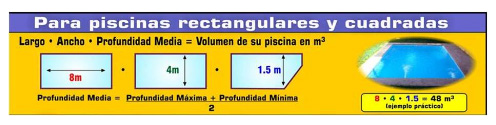

Calculate the volume of your pool

How much water contains my pool?

The water analysis and correction of potential problems can not be successful if you do not know how much water your pool contains, and also, you may be spending much more on chemical treatments in the long term. Here is a simple method to measure the number of cubic meters of your pool. Once you have this value, it is important that you bring when you order your water testing.First of all, you need to determine the average depth. The simplest method is to take a rope attached to a heavy object and measure the depth in the deep end, and then on the low side of the pool. Add these two values and divide by two to get the average depth. Use the value of the average depth in the following calculation to determine the volume of your pool.

For square and rectangular pools

Length x Width x Average Depth = Total cubic meters.Example: a pool measuring 10 meters long, 3 meters wide and has an average depth of 1.5 meters, containing 45 cubic meters of water.

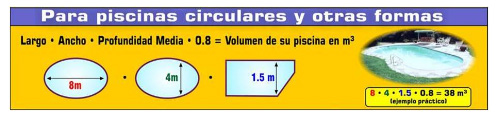

For circular pools, oval and Other Forms

Long Diameter x short diameter x average depth x 0.785 = Total cubic meters.Examples: if the diameter is 10 meters long, 4 meters short diameter and mean depth 1.5 meters, the pool contains 47.1 meters cubic.

Or a circular pool of 6 meters in diameter with an average depth of 1.5 meters, contains 42.4 meters cubic.

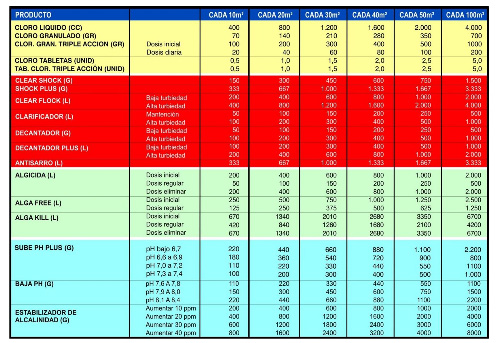

Calculate the dose of the Products to Apply

Chemical Dosage for structural pools

Chemical Dosage for kiddie pools

How to switch a green water to a transparent water in three days

Day 1

1- Measure your water pool with test.2- Stabilize water's pH and alkalinity, PH between 7.2 and 7.6 and alkalinity between 80 and 140 ppm.

3- Apply at night a shock of liquid chlorine, 3,000 cc each 10m3.

4- Apply 670cc of algae Kill each 10m3.

5- Filter the pool during the night.

Day 2

1- Make the pool's filter retro-wash.2- Algae dies, it is important vacuuming the bottom of the pool.

3- Brush walls and bottom of the pool.

4- Apply 100 cc each 10m3 of clarifier.

5- Measure level of free chlorine in the pool and if you are under 1 ppm apply liquid chlorine.

6- The pump should be filtering out all day.

Day 3

1- Make the pool's filter retro-wash.2- Vacuuming the bottom of the pool.

3- Brush walls and bottom of the pool.

4- Filter.

What to do if your pool has cloudiness

The first thing is to check the level of pH, alkalinity and chlorine from the pool. When the pH is out of range occurs cloudiness in the water.

If this is so you must adjust the levels with RAISE PH or LOW PH. The alkalinity and chlorine must be in the indicated range, otherwise, correct ranges.

If the cloudiness is due to the presence of particles in suspension, apply CLARIFIER, is a product to remove thin material in suspension, which are

permanent cause cloudiness in the water and many times impossible to delete only with the filtering process. The application of this product allows

a greater efficiency of the filter and therefore a clear crystal water and much more pleasant for the bathers.

If the cloudiness is accompanied with bad odor, there is a presence of chloramines in the water. Chloramines are formed with organic waste, which contain nitrogen, such as sunscreens, cosmetics, perspiration and others. The result of the chloramines is that do not allow the function of the chlorine sanitizer, producing chlorine odor, turbid waters and irritation of the eyes. The chloramines need to be destroyed (oxidized) for there to exist residual chlorine in the pool. The residual chlorine, or chlorine free, is the one that eliminates bacteria and algae. In order to do this, you must apply CLEAR SHOCK in your pool regularly, make sure you have high levels of free chlorine in your pool, giving it a proper hygiene, and keeping it protected from bacteria and algae.

What to do if your pool has stains

The first thing is to check the pH, alkalinity and chlorine level from the pool, in the event that they are out of range, correct the range. The pool can submit stains by corrosion accessories produced by problems in the pH, and by the existence of many minerals present in the water.To avoid the process of stains there is an anti-tartar toothpaste, this is a product to prevent and control the formation of stains on the walls of the pool, caused by sediments of different nature, such as limestone dissolved salts and iron, avoiding the cloudiness that is generated in the water, and cannot be deleted by the normal process of filtration.

What to do if your pool gets reddish-black

The first thing is to check the pH, alkalinity and chlorine level from the pool, in the event that they are out of range, correct the range.

When the chlorine pool water is added and placed red or black is due to the presence of iron in the water. When applying chlorine oxidizes

generating that color of water. To solve this problem it is necessary to apply a dose of liquid chlorine shock (3 times the stated on the packaging).

Apply CLARIFIER after, and filter 24 hrs.

This product coagulate the particles of iron to be large enough so that the filter captures them. As there is a cleaning action of the water, the filter

must be retro-washed more often.

Purification

One of the most important uses that man made is of water for consumption as a beverage. Water consumption allows the life of the species on the planet. Due to industrial development and population, water sources for consumption are increasingly polluted and purification process has become increasingly complex.

In the purification basically 5 stages are distinguished:

• Coagulation

• Flocculation

• Sedimentation

• Filtration

• Disinfection

Aguasin participates and has led the purification of water in Chile, precisely through the development of all technologies and products that

optimize the five stages described. Our company ensures optimum final water quality for consumption as a beverage.

Modular Plants

The water treatment plants must meet certain requirements to fulfill their purposes. One is to allow for simple and safe operation in time and are also

easy to transport, installation and commissioning. To accomplish the last one, Aguasin has developed water treatment plants with modular design, or on such

dimensions that allow their transport, assembly and operation in an agile and fast way.

These plants reached a size equivalent to one or more navy container (s) and processing capacity are designed so that each line or train, coupled to each other,

cover the user's requirement. Construction includes boards, power lines, control rooms, etc.

Generally the larger bodies such as ponds or filters, are positioned outside the module (container), and are interfaced with the systems that are inside. The size of the modular design makes it economically attractive to treatment flow rates of the order of 100 to 150 m3 / h of product. Above this size, it becomes more convenient and slab construction sheds

Water Recovery

The water is increasingly scarce and water recovery years ago only responded to an environmental necessity, today with high water demand and scarcity of natural sources,

has led companies to reuse and recover water in their production processes.

Aguasin has worked with clients in order to offer chemicals products and technologies that achieve this goal. In manufacturing our products help recovering clean water

from the capacitors, clean water used for washing, carry water in liquid-solid separation processes, water recovered in Industrial liquid waste treatment plant and

disinfect the water so they can be used without causing health problems.

Our technology can deliver water with purities greater than those we now deliver natural sources.

Our team of engineers and technicians is on hand to work together and find a solution to your problem of water recovery. We invite you to review our products where you

can find the solution to your problem.

Heavy Metals Reduction

As production processes have become increasingly complex and research on advancing human health, waste as "heavy metal" in the water content could be analyzed more accurately.

Their study has become a necessity because these residues may be grounds for benefits or harm in these processes and in the same human health.

Aguasin is involved in water treatment for the removal of these "heavy metal" through technologies such as micro and ultra filtration, which mitigate the damage caused by

these elements in production processes and human health. Furthermore, we studied the addition and measurement of these for useful purposes, such as corrosion inhibitors, disinfectants, etc.

Sanitation and Cleaning

Water quality impacts on operational costs, the state of maintenance of equipment and sometimes, if needed, perform corrective actions to maintain operational continuity.

Aguasin has professional equipment and technology to deliver solutions tailored to each case.

Must be performed a proper evaluation of the system and equipment involved in the circuit: metallurgy, fluid temperatures involved, and other aspects to consider,

to recommend the solution to the problem and prolong the life of the facility. In Aguasin we conduct a rigorous control of results after application of the products,

checking their effectiveness.

|

| Cooling Tower Washing. |

Within these services, we highlight:

• Boilers: chemical cleaning and passivation of new surfaces. DECASOL 830, 800 DECASOL, DECASOL 820, 840 DECASOL.

• Cooling Towers: chemical washes off line. DECASOL 300 to 800.

• Heat exchangers: CIP-type chemical cleaning of stainless steel and carbon steel. DECASOL 300, DECASOL 880.

• Stainless steel tanks: passivation equipment and related lines. DECASOL 890.

• Process Lines: descaling acid and alkaline cleaning. DECASOL DECASOL 800 850.

From the Department of Chemicals Aguasin, we advise our clients to implement programs for cleaning and disinfection.

|

|

| Boiler Previous Aguasin Chemical Cleaning | Boiler Later Aguasin Chemical Cleaning |

Services and Consulting

Among the services and advice made by Aguasin can include: a specialized technical assistance and consulting of water treatment process, purification, sewage, contracts, desalination and heavy metal reduction.

In the line of chemicals we mention testing, monitoring and selection of them to find the appropriate item for the process in question and determine the appropriate dose by our

representations of dispensing systems.

Our services and consultants have extensive experience in installation, commissioning, trial run, commissioning regime, preventive and / or corrective maintenance, systems

improvement, chemical cleaning of membranes, load changes, input supply, spare parts, monitoring and water analysis.

Dosing Systems

The basic objective of the systems developed by Aguasin is providing solutions to the various requirements that our customers have, applying standard type solutions or developing systems and applications to the suit of every need, always fully geared to meet the expectations of our customers. The line of dosing and control of Aguasin develops solutions in the following areas:

• Private chlorination systems, rural and industrial.

• Neutralization and control of pH systems.

• Dosing and control systems for cooling towers, boilers and closed circuits.

• Dosing systems for the most diverse mobile controls and product applications.

• Special dosing systems, designed for specific applications.

• Control systems and remote monitoring.

The developed industry has understood the need for investment in dosing and control systems that allow to have a better return on your business and safer operation, and has also decided to invest in automation that allows greater autonomy in their processes. Aguasin in these years of work has been devoted to search and integrate technology to meet the needs that our clients present us, having the following control and dosing systems, such as:

• Boiler Systems: Steam traps 1575 LAKEWOOD American.

• Cooling Tower Systems: Drivers 140 LAKEWOOD American.

• Chlorination Systems; flow proportional dosing LAKEWOOD 492, AquaClear. Americans. Chlorinators German MULTRONIC fine dosing.