Mining Processess

Water influences the processes producing unscheduled plant stoppages, increasing maintenance costs and decreasing the life of the equipment. Making a proper diagnosis, monitoring and water treatment can prevent these hidden costs and generate added value to the activities of our users.

This is why the division of chemical stuff develops products and control systems focused in the prevention of potential corrosives and fouling, notwithstanding the fact that also controls macro and micro fouling inside sea , fresh, processed and recovered water aqueducts from tailing dams to built up pools. It also optimizes the use of flocculants for the thickening process of tailing and condensation. Furthermore, it develops overall solutions to improve the solid and liquid split process performance.

The product line in this application is divided into those water conditioning additives and processes used for solid - liquid separation:

• DISPERSOL ®: Antiincrustives.

• PASIVAN ®: Corrosion Inhibitors industrial water and sea water.

• BIOSOL ®: Biocides.

• CLARISOL ®: Flocculants.

For further information contact the corresponding technical division.

In Aguasin we count with professionals dedicated to delivering the best solutions. Contact Us and we will answer your request.

Anticorrosives

Corrosive inhibitors are classified, according to the reaction that control, such as cathode or anode slimes. In response to the mechanism of action may react with the corrosive agent, form a protective film, or lead to the formation of an oxide film of the same metal that is trying to protect.

The selection is done according to the type of installation, the metallurgy and structural elements of construction, the design variables and the water quality of refitting.

Aguasin provides anticorrosive for different applications, such as:

• Water

• Acidic mine waters of superficial adduction

Aguasin does not use a corrosion inhibitor only. In general it is synergistically enhance two or more types of inhibitors complementing their individual advantages and overcoming the respective limitations. In addition it conducts studies on a case-by-case basis to define the best formulation according to the special characteristics of each client.

Aguasin has own formulations advised by BWA Biolab Water Additives Co. in that basic inhibitors are mixed with other components that enhance the individual characteristics of each product.

In this line, Aguasin sells their own brand PASIVAN ®.

Anticorrosive Sea Water

Water is an increasingly scarce in the mining and its rapid development in the North of Chile to forced to implement the use of sea water as

constant supply of the process; it fosters in the use of this resource geography of the country.

Lately, the driving of the sea water, coastal zone, toward labor, cordilleran zone, is an important part of the investment that must be made

for the mining supplies form and it regulates the physical characteristics of the chemical water, rich in sulfate and chloride, both catalysts

of the corrosion, that is why Aguasin has developed products for the control of the corrosion, which can reach values on the 50 pm and without

an adequate treatment.

With this objective aguasin sells their line of products PASIVAN ® 550

|

|

| Adduction sea water without treatment | Adduction with sea water treatment |

Antifouling

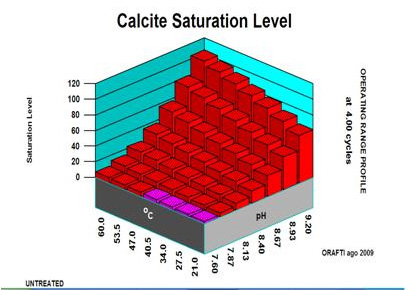

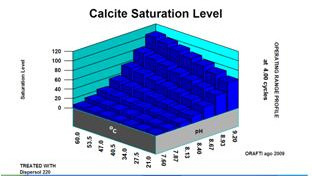

Antifouling is a chemical compound that has the property to prevent salts in the water are deposited (rush) in transmission lines, interchanges,

or any surface. This particular feature is due to three effects known as: threshold effect, distortion of crystals and dispersion. They work

synergistically allowing increase the saturation limits of encrusting salts. Normally these salts are carbonates, silicates and calcium sulfate.

Aguasin sells products to handle trends encrusting of sulfates, carbonates and silicates, among others, and conducts studies on a case-by-case basis to

define the best formulation according to the special characteristics of each client.

Aguasin provides antifouling in a wide range of processes, particularly in the mining areas, where trends fouling, such as:

• Drive Lines of fresh water.

• Drivelines of waters recovered from tailings (dam).

• Concentrate and mineral Transport Lines.

• Lines of recovery of water drain.

• Water Lines in concentrating especially waters overflow.

Aguasin uses specialized software for the treatment of water to make the diagnosis of the applications of chemicals.

|

|

| Projection Water without chemical treatment. | Projection with water treatment chemical. |

|

|

| Embedded Lines. | Embedded Lines. |

Biocides

The basic objective of the microbiological control in industrial systems is to prevent the problems associated with the microbiological growth.

The main problems associated with the growth of algae and microorganisms are:

• Problems to people's health.

• Generation of bio-film biomass or that affects the energy exchange.

• Contamination that lead to the clogging of the units.

• Microbiologically influenced corrosion.

It is not practical to sterilize all the circulating water by the very high cost. The use of broad-spectrum biocides is widely promoted,

however these biocide products must have the ability to limit the growth of a wide variety of microorganisms including bacteria, fungi,

algae and yeasts. In addition, must be effective in a wide range of operational conditions.

Aguasin has privileged the use of oxidizing biocides in industrial systems, since oxidizing biocides such as chlorine does not allow to

operate on ranges of Ph above 8. Our company offers a wide range of biocide products based primarily on isotiazoline and compounds not

organic bromide oxidants.

With this objective, Aguasin sells its products line of BIOSOL ®.

Flocculants

Flocculants are used in thickeners or concentrated sludge, with the purpose to increase the speed of sedimentation of the solid particles present in the water and thus obtain a current with the highest percentage of solids. For this reason, anionic flocculants are used to help increase the size of the particle, and so get an excellent rate of sedimentation. To evaluate the products to use tests of sedimentation which consists in comparing the different products and doses. This test seeks to find the best rate of sedimentation of the pulp and thus be able to recommend the product.