Reverse Osmosis

Reverse osmosis is to separate a component of another in a solution through the forces exerted on a semi-permeable membrane. Its name comes from "osmosis", the natural phenomenon by which water supply plant and animal cells to sustain life.

The basic components of a typical installation of reverse osmosis consist of a pressure tube containing the membrane, although typically use many of these tubes, arranged in series or parallel. A pump continuously supplies fluid to treat the pressure tubes, which is also responsible, in practice, to provide the pressure needed to produce the process. A control valve on the flow of concentrate is responsible for controlling it within the elements.

Aguasin manufactures and distributes chemicals to avoid natural problems of these systems, developing and distributing anti-fouling, biocides, coagulants and cleaners, to meet the full range of clients and applications, both within Chile and abroad.

In Aguasin we count with professionals dedicated to delivering the best solutions. Contact Us and we will answer your request.

Antifouling and Dispersants

Antifouling and dispersants are sell by Aguasin are synergistic blends of specific organic polymers in aqueous solution. They are designed to control a wide range of encrusting agents, such as sulfates, fluoride salts, silica and limestone, as particles in colloidal systems by reverse osmosis treatment of all kinds.

Depending on the nature of the product used, it allows to operate the processes of reverse osmosis with levels of silica in the concentrate of up to 250 ppm, this being a huge advantage in water recovery. Dispersants and anti fouling are effective even in the presence of iron. In addition, these are certified with ANSI/NSF 60.

The anti-fouling sell by Aguasin are compatible with all brands of membranes, effective with feed-water with a varied range of Ph. This feature allows you to delete the use of sulfuric acid in the operation of the plant of osmosis.

Aguasin is the exclusive representative in Chile of the following brands: CHEMTREAT® and FLOCON®, and sells its own brand name DISPERSOL®.

|

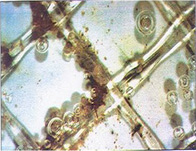

| Membrane collapsed by embedding |

Biocide Products

The main disadvantage of the membranes of polyamide is its intolerance to chlorine and other oxidizers. Without the implementation of a biocide product, microorganisms can rapidly colonize the membranes. The cumulative effects are manifested with increases in the pressure differential and deterioration of the quality of the permeated, dramatically reducing the life of the membranes.

Biocides in general, act at the level of the cell membrane of the microorganism, penetrating it and destroying the systems that allow the microorganisms to live. Biocide products cause lysis of the protein or lipoprotein wall of the body and penetrates its interior, interrupting the biochemical reactions that sustain life.

The biocide products sell by Aguasin has advantages such as a broad spectrum of activity, effective at low concentration, effective in a wide Ph range compatible with other chemical species in the middle, high persistence (must be effective through time), easy to neutralize (deactivators must possess mechanisms for their subsequent neutralization) and low human toxicity (must not be harmful in their safe handling by the operator).

Agusin is the exclusive representative in Chile for the brand: CHEMTREAT®, and sells its own brand name DECASOL®.

|

|

| Membrane with biological growth. | Vexar's Biological fouling. |

Coagulants

Chemical product of cationic nature that fulfill the function of destabilizing the ionic charge that has the water. These coagulants can be inorganic in nature (salts of aluminum) and organic (polyamides). Will depend on the feature of RIL, the coagulant to use. Aguasin sells the brand CLARISOL, being Clarisol series 2000 and Series 5000 Clarisol for this type of product. Our team of experts, evaluates the coagulant that will be used by making Jar Test trial, where they are experimenting with various products to different doses to deliver an approximation of what it is recommended to apply at the plant.

Evaporators

Sudden flash effect by Distillation (MSF)

The desalination is obtained by distillation in evaporate water to steam which does not contain salts (these are volatile from 300º C): The steam then condenses on the inside or outside of the tubes of the installation. The desalted systems typically operate below the atmospheric pressure and therefore require a vacuum system (pumps or ejectors), apart from the removal of the air and non-condensable gasses. The use of flash camera evaporation allows a sudden (and therefore of irreversibility) prior to their subsequent condensation. Generally, the camera flash is located in the lower part of a capacitor of the steam generated in the lower chamber. Therefore, the recovery of heat necessary for evaporation is obtained thanks to the union of successive stages in cascade to different pressure, and is the minimum contribution required from the condensation of a steam of low or medium quality from a power generation plant. This evaporative process is the most widely used in the world, massive deployment especially in the Middle East. This is due to several reasons:

• Is especially valid when the quality of the raw water is not good (high salinity, temperature and contamination of the water provided).

• Its coupling with power plants to form cogeneration systems is very easy and allows a high degree of variability of operating ranges in both plants.

• Its toughness in the daily operation compared to other distillation processes is notorious.

• The ability of the MSF plants is much greater than other plants distilleries in virtue of the amount of stages connected in cascade of operation without problems. However, MSF plants have a serious drawback. Its specific consumption, defined as the amount of energy consumed to produce 1 m^3 of desalinated water, is among the highest in the processes studied. This consumption contribute to the heat consumption from the plant producing electricity, higher than other distillation processes due to the flash effect; and the power consumption due to the large number of required pumps for the flow of plant. In addition to its high cost of operation, its installation cost is not lower than other desalination processes.

By multiple effect distillation (MED)

In contrast to the MSF process by flash effect, in the multiple effect distillation (MED) evaporation occurs naturally in one

side of the pipes of an exchanger taking advantage of the latent heat given off by the condensation of steam on the other side of the same.

A MED plant ( Multi-Effect Distillation) has several stages connected in series to different operating pressures, these effects have

each successive time the lowest boiling point by the effects of such pressure.

This allows the feed water to experience multiple boils in the successive effects, without the need to resort to additional heat from

the first effect. The salt water then transfers to the following effect to suffer a evaporation and the cycle repeats itself, using the

steam generated in each effect.

Normally there are also cameras flash to evaporate a portion of the salt water, it moves to the next effect, due to its lower operating pressure.

The first stage is fed by an external steam system spiraled, a-pressure turbine (or removing a condensation).

A final condenser picks up fresh water at the last stage by preheating the water input to the system. Therefore the plants also make up MED

cogeneration systems like the MSF consuming a portion of energy for the production of electricity.

The multiple effect distillation is a process not only used for desalination. The capacity of this type of plants tends to be lower than the SPS

(they rarely exceed 15,000 m^ 3/day) although this is more due to political reasons that operational: the larger MSF are installed in the Middle

East and the largest MED are installed in the Caribbean Islands to supply water to these areas of high pressure from tourism. It is also true that

the maximum number of effects connected in series is rarely more than 15, with the exception of the MED with multiple effects built into each one of them,

arriving in this case to a total number of more than 50.

However, they have a better overall performance with respect to a SPS: the ratio of gain in the distillers of this type of plant you can get to 15

without any problem, thus reducing the consumption of this specific process with respect to a SPS plant with identical capabilities.

This is mainly due to the irreversibility associated to the separation process flash that appears in the SPS processes. In addition the power consumption

is less than the MSF as it requires less circulation pumps in the absence of recirculation brine.

Aguasin distributes in Chile chemicals for the treatment of MED Equipment and MSF fouling products BELGARD ® and antifoam / Moisturizer BELITE ® of our represented BWA.

Thermal vapor Compression (TVC)

Compression of steam heat (TVC, Thermal vapor compression) gets the distilled water with the same process as a multiple effect distillation (MED),

but uses a source of thermal energy different: these are the so-called thermal compressors (or thermal-compresors), that consume half steam pressure

from the plant of electricity production (if we have a dual plant, but it would be a steam process obtained specifically for this) and that draws out

part of the steam generated in the last stage at very low pressure, compressed further and giving rise to a steam-pressure intermediate to the previous

suitable to be made to the 1st stage, which is the only thing that consumes energy in the process.

The performance of this type of plant is similar to the MED plants, however its desalination plant capacity may be significantly greater to afford

greater adaptability of steam outlet of producing plants of the same. Many times they are considered the same process, but here will be treated individually,

as energy consumption of the plant is done by a different team.

Aguasin distributes in Chile chemicals for the treatment of MED Equipment and MSF fouling products BELGARD ® and antifoam / Moisturizer BELITE ® of our represented BWA.

Cleaning Products

The membrane gets inevitably contaminated with the time. Therefore, the osmosis plant is going to present pressures higher than normal and the flow of water produced is going to be below normal.

Aguasin sells cleaners of generic and formulated types. These last, present a combination of buffering agents, surfactants, chelating agent, dispersant and Redox drivers, which in the great majority of the plants, minimizes the frequency of cleaning and reduce aggression against the membranes.

Aguasin sells its own brand name DECASOL®.

|

|

| Cleaned done with generic products and high generation of foam. | Study results cleaning. |

Membranes Repairers

With time the membranes, either by frequent cleanings or by the age of the same, lose their ability to reject salts which as a result brings a gradual increase in the conductivity of the permeated.