Boilers

Our products are aimed at controlling various problems in the boiler water and condensate return.

We can assure our customers that their plants operate at peak efficiency when using our products. We offer the following products for the treatment of steam generators and heating:

In Aguasin we count with professionals dedicated to delivering the best solutions. Contact Us and we will answer your request.

Corrosion for Condensate Line

Corrosion in condensate return systems originates mainly from the condensation of CO2 in the vapor. The presence of this gas produces a sharp drop in condensate pH, affecting the passives surfaces condensate circuit.

One way to control this type of corrosion is by applying neutralizing amines. Putting it in another way, neutralizing amines hydrolyze water to provide the OH-ions necessary to neutralize the acidity generated by the presence of CO2, in addition to directly react with it to neutralize its effect. Thus, the addition of amine is neutralized such that the corrosive effect of CO2 is upgraded and a pH between 8.5 to 9, because in this pH ensures the preservation of the layer of magnetite.

Aguasin counts with ALCAFOS line, formulated products based on amines which neutralize the acidity caused by carbon dioxide. This product acts in the initial stages of formation of condensate and in remote regions of the steam-condensate line, minimizing corrosion and sludge problems in the boiler, to avoid the presence of metal debris generated by corrosion in condensate head back.

Antifoam

Foaming problems in boilers are originated when working with high dissolved-solids content beyond the limits recommended by the operating characteristics of the boiler, and presence of organic pollutants. The formation of this foam problems causes the drag of water together with vapor, contaminating and reducing its polluting heat capacity.

DESPUMOL B-25 it´s a chemical product that prevents foam formation when its origin is an organic pollution or alkaline conditions of water; which can be applied on all types of steam boilers (high or low pressure)

DESPUMOL B-25 is compatible with any water treatment for boilers, which can be applied with other chemicals such as phosphates, sulfites, and other polymeric dispersants. Furthermore, it is miscible in water in all proportions.

Antifouling

When water is transformed into steam, the mineral contaminants existing in it are left inside the boiler and tend to precipitate causing fouling that are kept inside the boiler causing fouling that aisle the tubes, inhibit the effective heat transfer and produce overheating fuel consumption.

The most common fouling products correspond to salts associated to hardness (CA+MG) and quartz in the feed water. The boiler operation pressure defines the water quality that it is required, according to this, the pre-treatment and internal treatment type that is more adequate.

The product line DOSOFOS and POLISOL, are used for this application. The proper choice and dosage of the product depends on each system.

Oxygen Scavenger

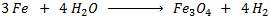

The water quickly rusts the iron surface and at high temperatures and it accelerates the reaction. The following reaction is the typical iron corrosion of the boiler generating magnetite, insoluble iron oxide

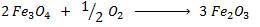

However, in the presence of oxygen, the magnetite layer formed is rapidly affected and converted into hematite (Fe203) generating focus of widespread corrosion and /or localized (pitting) that is irreversible, affecting the useful life of the boiler.

Aguasin counts with TIOXAN line, formulated with diverse ingredients of various active materials of oxygen scavenger action, passive agents and corrosion inhibitors.

|

| Pitting inner tube boiler, Aguasin without treatment. |