Disinfecting Equipment using ultraviolet Light

Water is the resource most used in industrial production processes at the global level; being in the majority of these critical control points, and at the same time, its

safety or disinfection one of the most important parameters.

Aguasin is the representative in Chile of TROJAN TECHNOLOGIESTM, the most important supplier of UV equipment industrial and municipal at the global level, with its lines AQUAFINE™, TROJAN-UVTM and Sterilight.

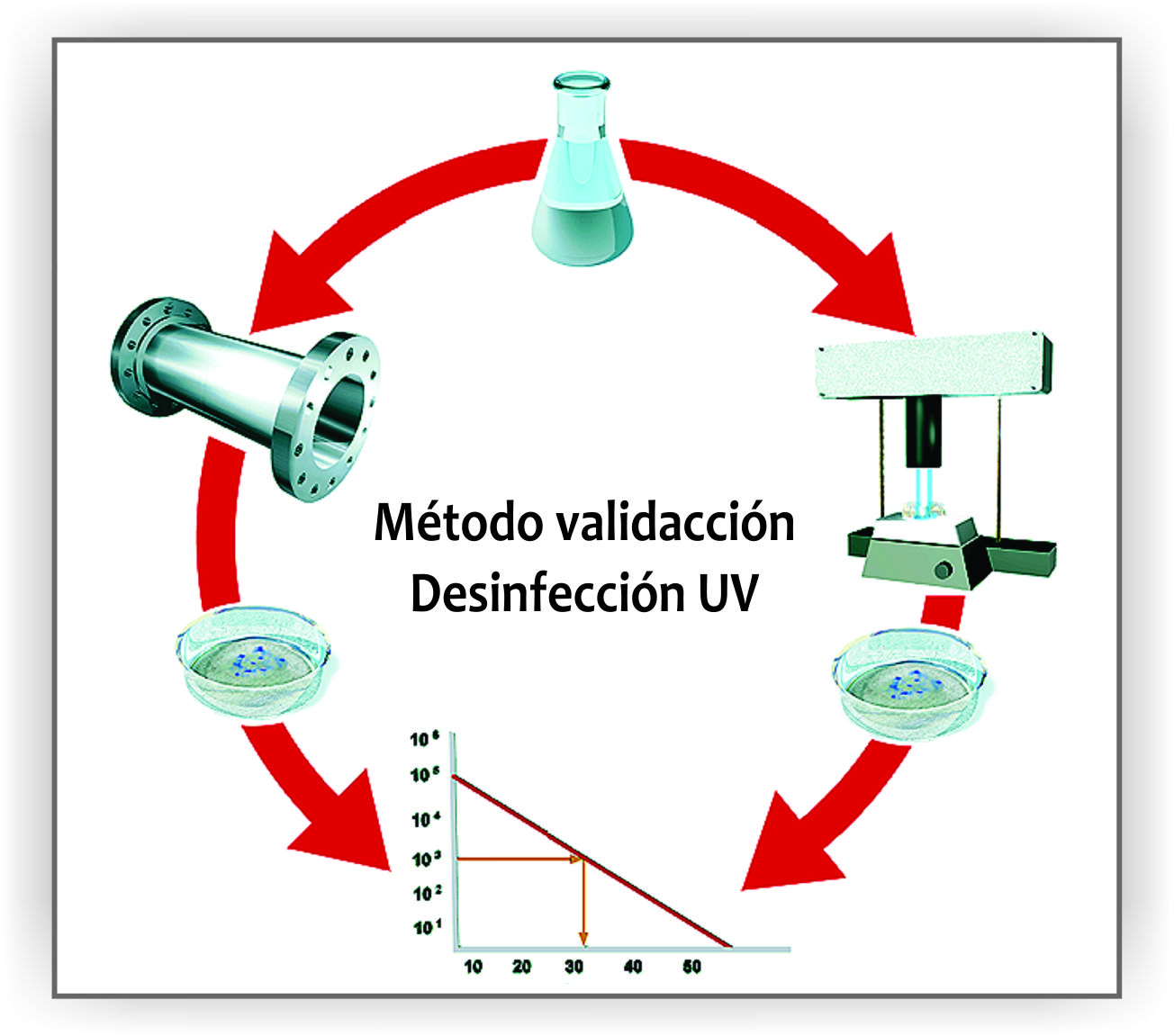

Validation, traceability and Bioassay

AQUAFINE® line, the world leader in UV equipment for the food and pharmaceutical industry, has validated systems and lamps by HDR HIDROQUAL (according to standard U.S. EPA) 4 Log NETWORK

(Reduction Equivalent Deuces), conducted at the center of UV validation and research of Johnstown, New York, United States; as also their UV sensors traceable standards under NIST

(National Institute of Standards and Technologies).

The technology of the bulbs "AMALGAM" of AQUAFINE® are validated through field testing " Bio-trials ", a methodology that ensures the disinfection of water as a function of the applied dose.

What is a bio-trial?

Is the methodology used and necessary to determine the dose of UV a UV equipment, where is measured the deactivation of pathogenic microorganisms, at different rates of flow rates and quality of water.

It is the only method that allows you to measure accurately parameters such as line spacing and number of lamps, efficiency of the ballasts, hydraulic flows, transmission of radiation in the quartz

and other variables that influence the performance of the disinfection.

All the AQUAFINE® and TROJAN-UVTM equipment comply with cGMP standards and U. S. FDA; optionally with sanitary connections in accordance with the DIN standards and U. S. DA 3-A

(Sanitary Standards Incorporated); certified EC (European Community), ANSI/NSF and certification "c UL us".

| • Wineries | • Water Treatment | • Process Plants | • Cooling Towers |

| • Breweries | • Hospitals | • Food Factories | • Agro-Industrial |

| • Bottling | • Aquaculture | • Industry Chemical | • Packing |

| • Laboratories | • Wellboat |

Semi Industrial Equipment (Small flow Rates)

Within the range of ultraviolet disinfection equipment with which Aguasin, is the mark Sterilight®, manufactured equipment to inactivate microorganisms chlorine-resistant such as Cryptosporidium, Giardia, E. coli; constructed in 304 stainless steel and UV lamps of mercury low pressure.

• Equipment for flow rates between 0.5 and 11.5 m3/h. UV dose.

• Adjustable according to level of required disinfection.

• Working Pressure of 8.6 bar (maximum).

• Failure Alarm and Hour-meter included in all the equipment.

• Low electrical consumption.

• 9,000 Hours of useful life of the UV lamp*

• 4-20mA signal (optional).

• UV radiation Monitor (on models SSM, CSM and platinum) in normal operation conditions.

*In normal operating conditions

|

|

|

|

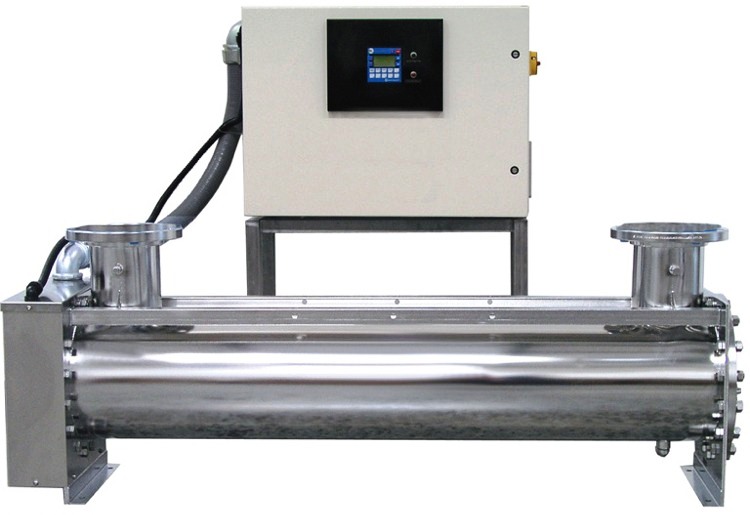

Industrial Equipment (Big flow Rates)

Aguasin is the representative in Chile of the brands Aquafine® Trojan UVTM Technologies; world leaders in UV disinfection technologies; equipment designed to meet the highest standards of quality and industrial health; built in stainless steel 316 L and lamps of technology "amalgam" and medium pressure.

• Equipment for flow rates between 2 and 294 m3/h.

• Validated equipment under standard U. S. EPA.

• Rebottled equipment by bio-trials (4 NETWORK Log Disinfection).

• Electrical Panel NEMA 12.

• Status of lamps, alarm fails, Hour Meter on all units.

Optional:

• NEMA 4X stainless steel 304 Electrical Panel.• Microprocessor control UV Vision-2000TM.

• UV Sensor and operating temperature.

• UV radiation Sensor 4-20 mA.

• Manual/automatic operation switch (24VDC).

• Valve for sampling.

• Health Connections.

• Validated lamps for 9,000 hours.

• Cleaning System manual/automatic.

|

|

|

Equipment designed for disinfection of large water flows and destruction of chloramines, UV lamps are used for medium pressure, which significantly reduces the size of the UV reactor, making installation in tight spaces such as rooms of machines (wellboats).

• Equipment for flow rates between 179 and 700 m3/h.

• Electronic Ballasts.

• UV G-500 controller.

• UV Sensor radiation.

• Temperature Sensor.

• Indicator UV dose.

• Automatic cleaning system.

• 4-20MA signal; 24 VDC.

The Trojan UV-3000 equipment and Trojan UV-4000, are open channel systems, are designed for the disinfection of both tributary as effluents from large flows of water; primarily used in the aquaculture industry and municipal treatment.

For more information about these units communicate directly to our offices.

|

|